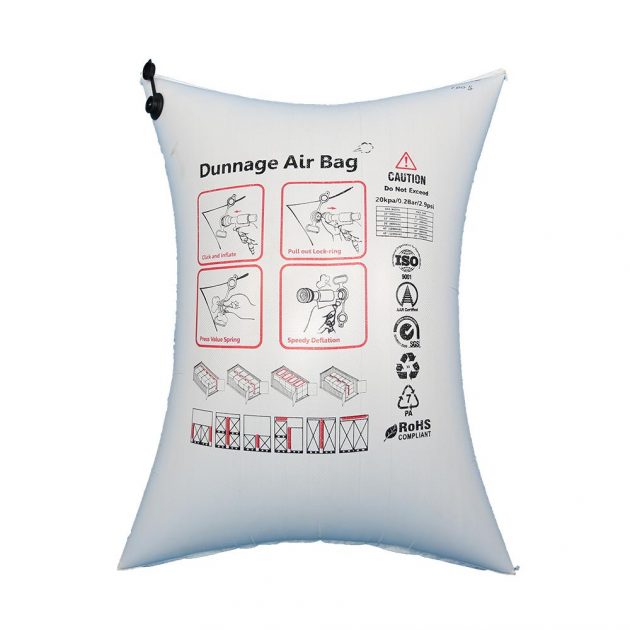

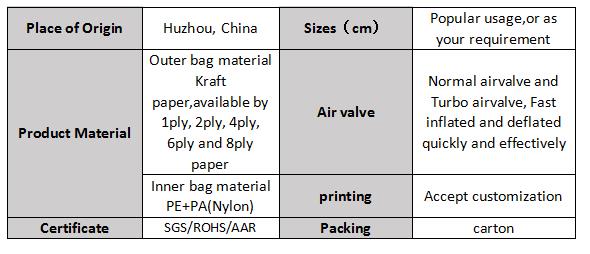

Paper dunnage bags are made out of two components, an inner component that consists of a polyethylene inner bag, the outer component is a paper bag. The outer bag is made of the highest quality, light weight kraft paper of high tensile strength. Paper dunnage bags come in different strengths and varieties and can be made in any special size. The inner component provides optimum pressure and the outer component provides optimum strength. For use in the chemical industry paper dunnage bags can be polycoated. A polycoat will make the dunnage bag resistant to specific chemicals.

Improved Stability for Pallet Loads—The unique design of dunnage bags ensures superior stability and stability for pallet loads. The inner layer of woven PP cloth provides additional strength and durability, while the inflation valve seals the bladder to ensure quick inflation and deflation with a single air-inflator gun. This ensures that pallet loads remain stable while in transit, even under harsh conditions such as extreme temperatures and shocks from long-distance travel.

Increased Efficiency & Cost Savings—Inflatable dunnage bags are far more efficient than traditional methods of packing and stabilizing cargo. With an air-inflator gun, you can quickly inflate the bags, eliminating the need for manual labor and reducing overall costs. Furthermore, due to their lightweight and inflatable design, they take up less storage space than other packaging materials. This increases efficiency and cost savings, allowing businesses to maximize profits with minimal effort.

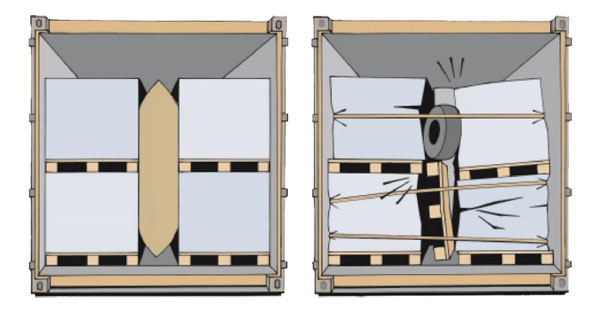

Enhanced Protection for Your Goods—By using dunnage airbags, you can rest assured that your goods are safe and secure. The airbag design helps to evenly distribute the weight of the cargo, reducing the risk of damage while in transit. This enhanced level of protection reduces your losses and keeps your customers satisfied.

Quick Details

Dunnage Bag Application