During the production and transportation process, many products are contained in barrel-shaped containers. Due to the physical and chemical properties of some products, it is impossible to use iron barrels to contain them, and the barrel diameter of the barrel is not uniform. During transportation, the stacking is not neat or fixed, which leads to a series of things caused by the leakage of the product in the container. It may be considered to use the best polyester cord strapping for fixing and binding when shipping.

The barrel loading generally includes various oils, liquids and powder chemicals, etc. There are three different barrels of materials: iron barrels, wooden barrels and plastic barrels; IBC barrels are generally filled with liquid products.

1. Common iron drums in container transportation

This kind of iron drum is 0.25m3 (55 gallons). Generally, two layers are stacked vertically in the container. Each 20-foot container can generally hold 80 drums.

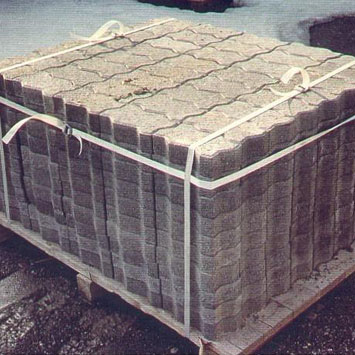

Different manufacturers will have different loading methods. For example, some manufacturers put them directly in containers, and some put them on pallets first and then use forklifts to load them into the containers.

IBC barrels are usually placed directly in the container. Whether it is an iron drum or an IBC drum, it needs to be reinforced with packing straps or other products when it is loaded to the door to prevent movement.

2. Reinforcement of special barrels

Drum-shaped wooden barrels generally have iron hoops at both ends. Because it is easy to remove the cover when installed vertically, in principle, horizontal installation is required. When lying horizontally, a wooden wedge should be placed on both ends of the wooden barrel. The height of the wooden wedge should be such that the center of the barrel can leave the bottom of the box and the waist of the barrel is not stressed.