In order to prevent the loading and unloading of boxes during transportation, or the loading and unloading of ships at the transshipment port to damage the goods, causing the boxes to sway in the container and cause damage, they will choose strap reinforcement or use fillers (dunnage bags) to avoid losses.

Bagged cargo is also commonly seen in container transportation. The main ones are food, cocoa, fertilizer, cement, corn flour, powdered chemicals, etc., and their packaging forms will be different, including sacks, cloth bags, plastic bags, paper bags, etc.

(1) For paper bags filled with cement, sacks filled with grain, and cloth bags filled with powder, before packing, a layer should be paved on the container floor to prevent the products falling out of the bag from damaging the container.

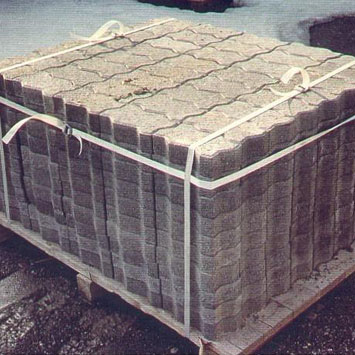

(2) The bagged goods will generally bulge in the middle. After being loaded, it will not be as stable and ignorant as the paper bag, so it needs to be placed layer by layer, and the wall stacking method and the staggered stacking method can be used.

(3) After the bagged goods are placed in the container, it is easy to move during transportation, so we use adhesives between the bagged goods or insert a liner board and non-slip rough paper to prevent sliding.

(4) If the bag is loaded very high, the goods can easily slide down near the door of the box, so some reinforcement products such as packing straps need to be used to fix it at the end of the door to prevent collapse It is also a consideration of the safety of loading personnel when unpacking.