Baling tape, a seemingly simple yet indispensable component in the world of packaging and recycling, has undergone significant evolution over the years. From its humble beginnings as a means to bind together loose materials for easier handling, baling tape has become a sophisticated material that plays a crucial role in the logistics and environmental sustainability of various industries.

The core function of baling tape is to provide a strong, secure bond to the materials being baled, ensuring that the bales remain intact throughout the entire process, from compression to transportation and storage. The tape's durability is paramount, as it must withstand the immense pressure exerted during the baling process without tearing or losing its adhesive properties.

The evolution of baling tape can be traced back to the introduction of synthetic materials such as polypropylene and polyester, which replaced earlier materials like cotton and jute. These synthetic tapes offered superior strength, resistance to moisture, and a longer shelf life, making them ideal for use in a wide range of environments and applications. The development of these materials has allowed baling tape to become a staple in industries such as agriculture, construction, and recycling, where the handling of large quantities of materials is commonplace.

One of the most significant advancements in baling tape technology has been the introduction of high-strength, high-tack adhesives. These adhesives ensure that the tape maintains a strong bond even under extreme conditions, such as high humidity or temperature fluctuations. This has been particularly beneficial in outdoor applications, where the tape is exposed to the elements, and in the recycling sector, where the tape must secure a variety of materials that may have different surface properties.

The environmental impact of baling tape has also been a focus of innovation. As the world becomes increasingly aware of the need for sustainable practices, the development of biodegradable and recyclable baling tapes has become a priority. These eco-friendly options are designed to break down naturally or be recycled, reducing the environmental footprint of the packaging and recycling process.

Another area of innovation has been the development of tapes with specialized properties, such as UV resistance, which is essential for outdoor applications where the bales may be exposed to sunlight for extended periods. This innovation ensures that the tape remains effective even in challenging conditions, maintaining the integrity of the bales.

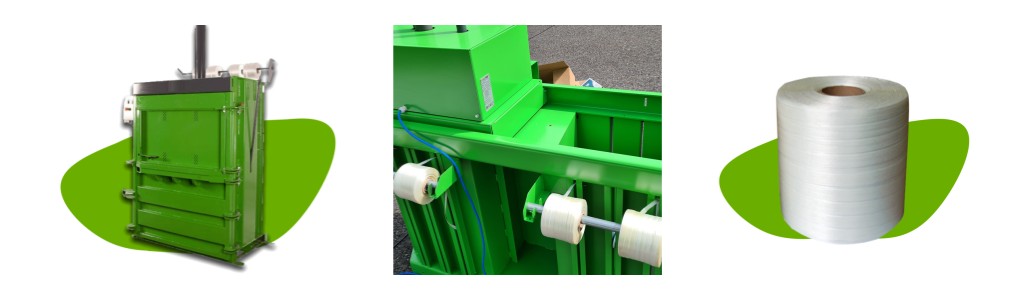

The application of baling tape has also become more user-friendly, with the introduction of automated baling machines that can apply the tape with precision and speed. This not only increases efficiency but also reduces the potential for human error, ensuring that each bale is secured to the highest standard.

In conclusion, baling tape has evolved from a basic binding material to a sophisticated component that is integral to the efficiency and sustainability of modern packaging and recycling processes. Its strength, durability, and adaptability have made it a versatile tool in various industries, and its continued evolution promises to further enhance its role in the future of logistics and environmental stewardship. As the demand for sustainable and efficient packaging solutions grows, baling tape will undoubtedly continue to play a pivotal role in meeting these challenges.