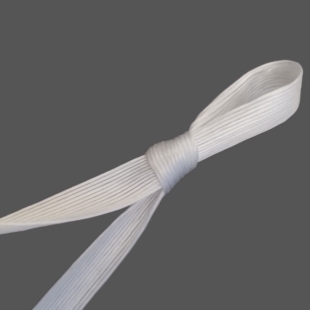

Introduction to Hot Melt Corded Strap

In the modern logistics and transportation industry, the choice of packing tools is crucial for ensuring the safety and integrity of goods. The Hot Melt Corded Strap has become a popular packing solution due to its excellent performance and reliability. Although it shares similar uses with Composite Strap, there are significant differences in manufacturing processes and materials.

1. Characteristics of Hot Melt Corded Strap

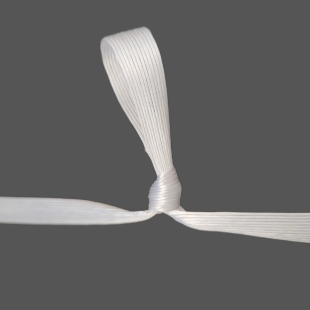

Hot Melt Corded Strap is typically made from polymers and fiber materials, utilizing a thermal bonding process. This process allows the strap to melt quickly when heated, creating a strong bond. Here are some key features of Hot Melt Corded Strap:

- **High Strength**: The hot melt strap has outstanding tensile strength, making it ideal for bundling heavy items and ensuring stability during transportation.

- **Anti-Slip Design**: The surface design of the strap usually features anti-slip properties, effectively preventing goods from shifting due to friction during transport.

- **Environmental Resistance**: It exhibits strong resistance to temperature and humidity, making it suitable for various challenging environmental conditions, widely used in warehousing and outdoor transport.

- **Ease of Use**: The hot melt strap is very simple to use; it only requires a heat source for processing, saving both time and costs.

2. Comparison between Hot Melt Corded Strap and Composite Strap

While both Hot Melt Corded Strap and Composite Strap are used for packing, they differ in their manufacturing processes and performance characteristics:

- **Material Composition**: Composite Strap is typically made from multiple layers of different materials combined, focusing on providing a blend of flexibility and strength. In contrast, Hot Melt Corded Strap relies on thermal bonding technology to create a robust connection at the joints.

- **Application Scenarios**: Although both can be used for bundling heavy items, Hot Melt Corded Strap performs exceptionally well in high-temperature or humid environments, making it suitable for situations requiring strong environmental resistance.

- **Connection Method**: Composite Strap often uses metal or plastic fasteners for connection, whereas Hot Melt Corded Strap achieves bonding through thermal melting, reducing the need for additional components.

3. Applicable Industries and Applications

Hot Melt Corded Strap is widely used across various industries, including:

- **Manufacturing**: For packaging and securing machinery and electronics during production and transportation.

- **Warehousing and Logistics**: Providing safety assurance in the storage and handling of goods.

- **Retail**: Bundling products to ensure neatness and safety during transport.

Conclusion

With its unique manufacturing process and superior performance, Hot Melt Corded Strap has become an indispensable tool in the modern packing industry. Whether it is for securing heavy items or for reliable use in challenging environments, it demonstrates significant value. With advancements in technology, it is believed that Hot Melt Corded Strap will gain wider recognition and application in more fields.