In the world of packaging and shipping, securing goods during transport is paramount to ensuring their safe arrival at their destination. Traditional strapping materials like steel and plastic have long been used for this purpose, but in recent years, composite strapping has emerged as a popular and versatile alternative.

What is Composite Strapping?

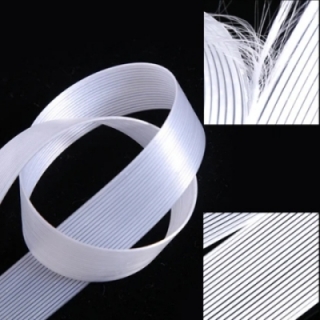

Composite strapping, also known as polyester composite strapping or cord strapping, is a type of strapping material made from a combination of high-tenacity polyester fibers and a protective polymer coating. This unique blend of materials provides composite strapping with a range of desirable properties that make it well-suited for a variety of applications.

Key Advantages of Composite Strapping

High Tensile Strength: Composite strapping boasts exceptional tensile strength, enabling it to withstand heavy loads and dynamic forces during transport. This makes it an ideal choice for securing palletized goods, machinery, and other bulky items.

Superior Impact Resistance: The combination of polyester fibers and polymer coating in composite strapping imparts excellent impact resistance. This property is crucial for protecting goods from damage caused by shocks, vibrations, and rough handling during transit.

Lightweight and Flexible: Unlike steel strapping, composite strapping is remarkably lightweight, making it easier to handle and apply. Its flexibility allows it to conform to irregular shapes and surfaces, ensuring a secure and snug fit around the load.

Non-Abrasive and Rust-Proof: The protective polymer coating of composite strapping prevents it from scratching or damaging the products it secures. Additionally, its resistance to rust and corrosion makes it suitable for use in outdoor environments and harsh conditions.

Environmentally Friendly: Composite strapping is considered an environmentally friendly alternative to steel strapping. It is recyclable and has a lower carbon footprint during its production and disposal.

Applications of Composite Strapping

The versatility of composite strapping makes it a popular choice across a wide range of industries, including:

Logistics and Shipping: Securely bundling and palletizing goods for transportation by land, sea, or air.

Manufacturing: Securing components, machinery, and finished products during production, storage, and shipping.

Construction and Building Materials: Reinforcing and stabilizing building materials, such as lumber, pipes, and concrete blocks.

Recycling and Waste Management: Bundling and securing recyclable materials and waste for efficient transport.

Choosing the Right Composite Strapping Solution

When selecting composite strapping, it is essential to consider the specific application and load requirements. Factors such as breaking strength, strap width, and elongation percentage should be carefully evaluated to ensure optimal performance. Additionally, the choice of buckles and tensioning tools plays a crucial role in achieving a secure and reliable strapping solution.

Conclusion

Composite strapping has established itself as a valuable asset in the packaging and shipping industry. Its combination of strength, durability, versatility, and environmental friendliness makes it a preferred choice for securing a wide range of goods during transport and storage. As demand for efficient and sustainable packaging solutions continues to grow, composite strapping is poised to play an even more prominent role in the years to come.